With its sleek look and seemingly simple function, aluminum structural framing is an unsung hero of manufacturing. Versatile, easy-to-use, and practical in a variety of applications, aluminum framing offers numerous advantages across multiple facets of the user’s respective industry.

But effectively using aluminum framing starts in the design phase – before a physical extrusion is even in your hand. With the right design tools and aluminum framing system, turn any vision into a reality with the portfolio that provides everything to build anything.

But effectively using aluminum framing starts in the design phase – before a physical extrusion is even in your hand. With the right design tools and aluminum framing system, turn any vision into a reality with the portfolio that provides everything to build anything.

Simplify the Design Process With Digital Tools

Without the ability to easily conceptualize and customize your solution, aluminum framing is just a pile of profiles and connectors. Compatible, easy to use, design tools are a critical part of an aluminum framing product offering – allowing design engineers to create fully customized solutions for their unique applications.

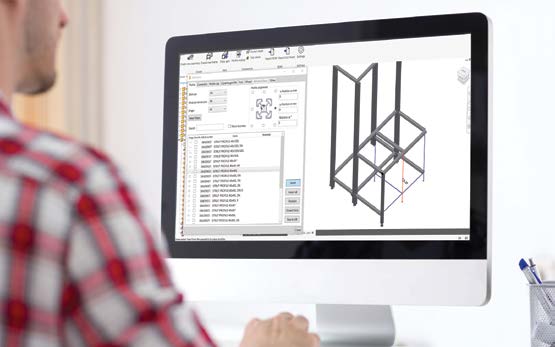

To support design engineers, Bosch Rexroth offers several digital tools that simplify the planning and design of aluminum framing projects. MTpro, the free digital planning and design software, makes it easy to configure and customize projects on your own, though a network of national distributors are also available for turnkey assistance. Drag and snap components to build assembly layouts and access a complete library of configurable 3D models that can be exported or directly inserted into common CAD systems.

MTpro makes it easy to configure and customize aluminum framing projects on your own.

Using MTpro, Rexroth customer, Berlinger Special AG, was able to put an entire assembly line into operation in less than three months. In MTpro Layout Designer, assemblies such as worktables or shelf systems were individually designed, adjusted to the body size of the employees using the ManModel function and inserted with millimeter precision in the 3D layout of the virtual working environment. MTpro not only provided support with layout planning, but also generated ready-to-order parts lists with all necessary assemblies and elements once the project was ready to bring to life.

FRAMEpro brings proven basic mechanic elements into familiar CAD environments.

The latest addition to the aluminum framing digital tool belt, FRAMEpro brings proven basic mechanic elements to the CAD programs Autodesk® Inventor and SOLIDWORKS from Dassault via plug-in. The seamless integration of the component library and numerous supporting functions reduce design outlay, prevent errors as far as possible and lower the engineering costs. Selected profiles are placed in a 3D line model before accessories are added. Thanks to constant updates, FRAMEpro is always up to date, which means that there is no need for manual imports and transmission errors are avoided.

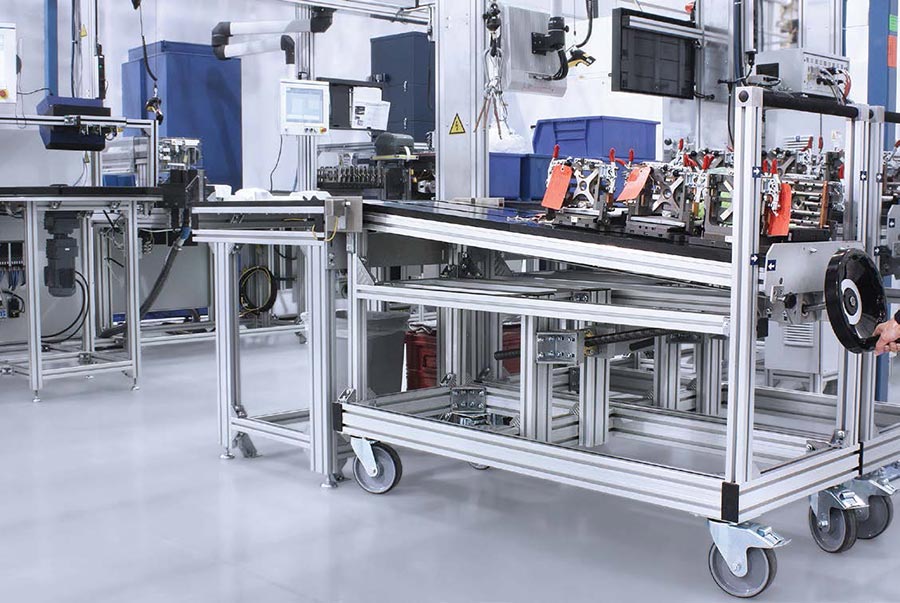

Design Outside the Manufacturing Box With Aluminum Framing

With aluminum framing, thinking outside the typical manufacturing box is encouraged. The versatility of aluminum framing allows it to be used in a wide range of applications and industries. Even applications from industries as strict as medical manufacturing are no challenge for the right aluminum framing system. With a flexible product offering that includes framing designed and independently certified for cleanroom manufacturers, cleanroom profile systems by Bosch Rexroth eliminate particulate-trapping surfaces, minimize out-gassing and enhance airflow for adherence to cleanroom and medical manufacturing regulations. Build machine bases, material shuttles, tables, cabinets and almost anything else for clean production with a full range of extrusions, connectors, and accessories uniquely engineered for a medical environment.

Aluminum framing can be found in applications such as battery module assembly.

Continuing outside the standard manufacturing environment, aluminum framing can also be found in industries such as aerospace. Extrusions and connectors can easily be assembled to create sturdy ladders, platforms and more for aircraft maintenance applications. But the building fun doesn’t end with manufacturing, medical and aerospace. Aluminum framing fits into architecture with a snap.

Aluminum framing being used as components for solar line production

Using a little creativity and engineering ingenuity, aluminum framing has taken the form of museum gift shops, a picture gallery, barges and fabricated housing, with more structures constantly being developed. With an aluminum framing system that provides everything, building anything is limited only by the imagination. Outside of the above-mentioned industries, aluminum framing has made its mark on robust industries including semi-conductor, packaging, solar and more. When thinking outside the box, the applications are near endless.