In cold-forming processes for assembling parts, various factors, such as part design, material properties, and orientation, can sometimes lead to unexpected results. To mitigate these challenges, the need for clamping before and during forming often arises. While incorporating clamping into part fixtures is ideal, Orbitform offers a cutting-edge alternative with their Thru-Spindle Pressure Pad. This innovation is designed to apply a secure clamp-load prior to and during the forming process, making it a game-changer for manufacturers seeking assembly precision in their assembly processes.

Introducing Roller Forming

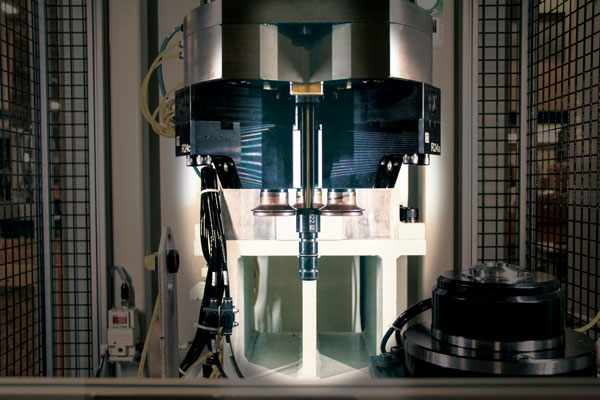

Before delving into the Thru-Spindle Pressure Pad, let's first understand Roller Forming. This advanced technique involves the application of 360 degrees of symmetrical force around a cylindrical part, utilizing two or more rollers. Roller Forming has gained prominence as a non-impact process that outperforms traditional methods like press crimping, which as a result to higher forces being induced into the part, can introduce material cracking and result in inconsistent forms. Orbitform has been at the forefront of Roller Forming since 2005, offering two distinct applications: Static and Articulating. These processes empower manufacturers to create smooth lips, add grooves, flare tubular components outward, or form undercuts with unparalleled precision.

Before delving into the Thru-Spindle Pressure Pad, let's first understand Roller Forming. This advanced technique involves the application of 360 degrees of symmetrical force around a cylindrical part, utilizing two or more rollers. Roller Forming has gained prominence as a non-impact process that outperforms traditional methods like press crimping, which as a result to higher forces being induced into the part, can introduce material cracking and result in inconsistent forms. Orbitform has been at the forefront of Roller Forming since 2005, offering two distinct applications: Static and Articulating. These processes empower manufacturers to create smooth lips, add grooves, flare tubular components outward, or form undercuts with unparalleled precision.

The Thru-Spindle Pressure Pad: An Industry Exclusive

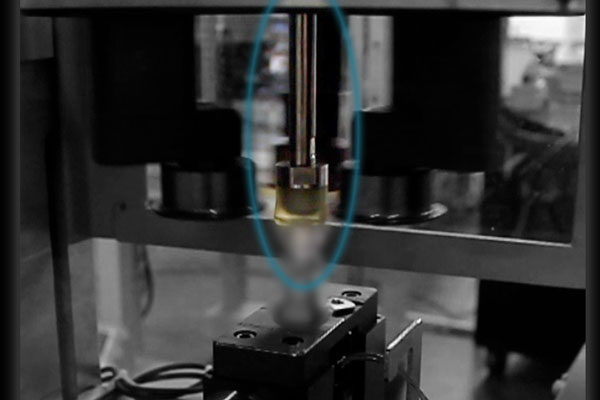

Orbitform's Thru-Spindle Pressure Pad stands as a unique solution within the process of Roller Forming. While the company's Orbital and Radial Pressure Pads are designed to attach to the outside of orbital or radial heads, the Thru-Spindle Pressure Pad takes a different approach. This ingenious device is installed through the center of the powerhead spindle, aligning directly with the forming head package without tooling interference. The powerhead is equipped with an offset motor drive to ensure clearance for the pressure pad. This setup guarantees that the clamping of components can occur prior to and during the forming process without interfering with the rollers.

The Thru-Spindle Pressure Pad is helpful in various applications where clamping is imperative, such as preventing internal components from moving during the forming cycle or achieving specific compression forces, especially when creating airtight seals or ensuring structural integrity.

Precision and Partnering with Orbitform

Employing the Thru-Spindle Pressure Pad alongside Orbitform's Roller Forming Processes is a strategic move for manufacturers striving for precision and consistency in their assemblies. With nearly four decades of experience in the industry, Orbitform's Assembly Experts are well-equipped to help identify the correct assembly process and recommend essential machine options like the Thru-Spindle Pressure Pad to guarantee success.

To embark on a journey towards enhanced precision and impeccable assembly outcomes, reach out to Orbitform today. Let us collaborate with you to discover the optimal solution tailored to your specific needs. With Orbitform as your partner, you can be confident in achieving the highest standards of precision and quality in your assembly processes. Contact us today to discuss your next assembly application and experience the Orbitform advantage.