Recently, an automotive manufacturer contacted Orbitform for a customized solution for their hood hinge assembly. The product required several machines with different forming processes to complete the sub-assemblies. While the methods included many of Orbitform’s standard processes, they also involved one of our lesser-known capabilities – bushing flare and flatten.

Sequence of Operations

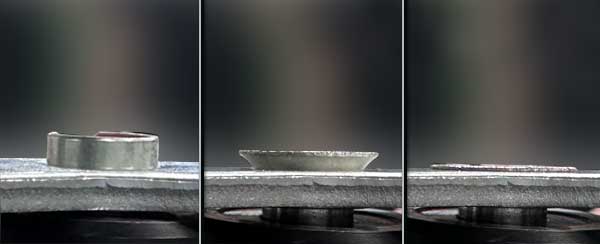

Leveraging our powerhead as a press, Orbitform completed the bushing flare and flatten process in two locations with a multi-tool head. The sequence of operation was as follows:

- The operator loads two parts

- Powerhead advanced to flare out bushing

- The powerhead tool rotated and moved to flatten the bushing

- 2-position slide advanced, bringing the second bushing directly under the tool

- Powerhead advanced to flare out the second bushing

- The powerhead tool rotated and advanced to flatten the second bushing

- The slide retracted to the operator load station

Dedicated Left and Right

Due to the nature of the automotive industry, parts consisted of right and left-handed orientation. To help combat the confusion, Orbitform provided two machines dedicated to each side. Leveraging a poka-yoke process, part presence detection was added to ensure the correct parts were loaded in the corresponding machine. To prevent bad parts from entering the field, each station included vision systems to check for the completion of the process.

Multiple Sizes, Multiple Parts

To help create a machine that could form multiple link sizes, we added a servo-z mechanism for programable height adjustments. The addition allowed for a quick height adjustment through the touch of a button on the HMI display. Each part had its program that could be selected. The operator would select the part on the touchscreen, and the proper program would form the parts.

The Final Solution

Upon completion, the customer was given a machine with two powerheads on one common base capable of forming four bushings in one cycle. The unique system could achieve volume requirements while leveraging only one operator, thus increasing throughput.

Orbitform has developed many custom equipment solutions for a bushing flare and flatten. We welcome the opportunity to review your application and partner with your team to develop your unique forming system. Contact us today to speak with our Fastening and Forming Experts.