Material, coating, and geometry all play a part in the finished form. When designing assembly applications, knowing how the part will react during assembly is essential. Based on how the application reacts when pressure is applied, some parts require clamping during assembly to ensure they meet functional requirements. If this is not achieved with a fixture, Orbitform offers various pressure pads to secure the workpieces during the forming cycle.

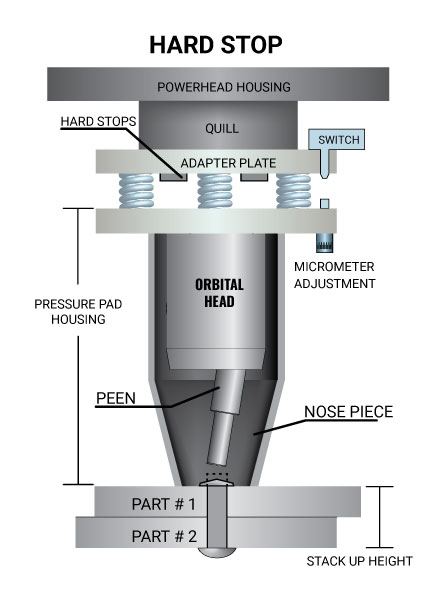

The Hard Stop Pressure Pad

An automotive manufacturer needed to install a washer into a compressor assembly using an Orbital Riveter. During the forming process, pressure was applied to the washer and caused it to bend and cup upward. This was unacceptable, as the application required the washer to remain flat.

Orbitform installed a Hard Stop Pressure Pad onto the Orbital Riveter to solve this challenge.

The Hard Stop Pressure Pad

The pressure pad was mounted to the end of the powerhead quill and consisted of an adaptor plate, housing, and nosepiece.

- The pressure pad advanced first until the nosepiece engaged with the washer, forcing it to stay flat.

- The powerhead then advanced until it “dead-headed” against the pressure pad via internally mounted hard stops, applying the full force of the powerhead to the washer.

- A limit switch and micrometer mounted to the pressure pad controlled the dwell time or how long the peen was in contact with the part. This type of pressure pad ensured that the distance between the face of the pressure pad and the forming tool was always the same, precisely controlling the finished form height.

The Hard Stop Pressure Pad provides a unique solution for consistency and precision. Orbitform also offers several other pressure pad options:

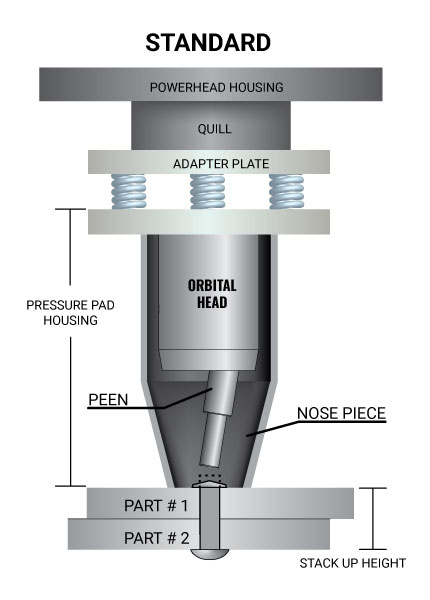

The Standard Pressure Pad

Our Standard Pressure Pad is spring loaded with approximately 1/4" difference between the end of the nosepiece and the peen.

- The powerhead advances

- The nosepiece engages with the part and applies a preload force to clamp the part in place.

- The peen continues to advance to form the part, after which the powerhead, pressure pad, and peen all retract.

While the clamping force can be increased or decreased if required, the average force applied with the pressure pad is around 350 pounds.

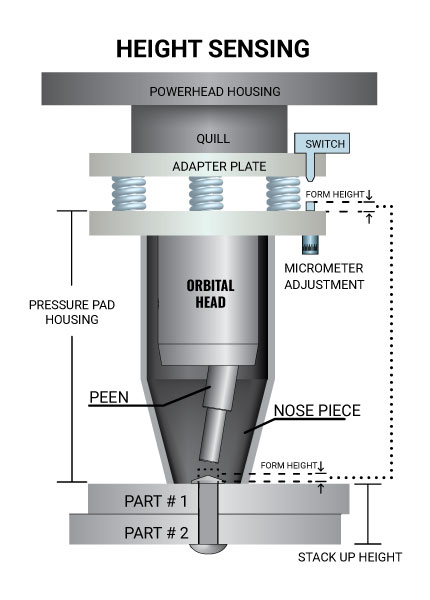

The Height Sensing Pressure Pad

The Height Sensing Pressure Pad is similar to the Hard Stop Pressure Pad. The form height is determined by finding the part's surface and forming an offset distance. However, the basic height-sensing pressure pad uses the limit switch and micrometer to control the form distance instead of a hard stop. The limit switch/micrometer tells the powerhead when to retract, and the part does not take the full force of the powerhead. This benefits manufacturers with variations in part stack-up that result in inconsistent final form heights.

The Programmable Height Sensing Pressure Pad

Our Programmable Height Sensing Pressure Pad is one step above the Height Sensing Pressure Pad. This pressure pad uses an LVDT instead of the limit switch/micrometer to measure the rivet length before forming. When paired with other process intelligence equipment, the riveting operation will not be initiated if this pressure pad detects measurements outside the specified ranges.

The Thru-Spindle Pressure Pad

For our Roller Forming process, we offer a Thru-Spindle Pressure Pad to compress components together before forming. It is installed through the center of the powerhead spindle directly in line with the forming processes and requires that the powerhead has an offset motor drive. This is beneficial when specific compression forces are necessary, such as when forming a seal.

Increased Quality and Precision

When precision and consistency from part to part are critical, manufacturers can significantly benefit from incorporating a pressure pad on their equipment. Pressure pads increase the quality and quantity of good parts produced from clamping the workpiece in place to measuring for correct parts pre-assembly. Contact Orbitform’s assembly experts today to determine how your assembly operations can be improved by adding one of our pressure pads.